|

TOP TECH INCORPORATION |

INDEX

1. COMPANY DESCRIPTION 2. ORGANIZATION 3. SERVICE CONTRACT 4. LIST OF REPAIRED ROBOTS BY TOPTECH (2003) 5. ROBOT ASSEMBLY |

|

1. COMPANY DESCRIPTION |

COMPANY: TOP TECH INC.

ADDRESS: NO.1003, 1004 Suntech City, 513-15, Sangdaewon-Dong

Joongwon-Gu

Sungnam-City, Kyeonggi-Do, 462-807, Korea

TEL: 82-31-777-1250

FAX: 82-31-777-1268

◈ BUSINESS DESCRIPTION

♣ ROBOT REPAIR & OVERHAUL

(TRANSPORT AND MEASUREMENT

EQUIPMENT FOR LCD & FAB SYSTEM)

♣ ROBOT UP-GRADE

♣ ROBOT REFURBISHMENT

◈ ROBOT MAKER

♣ GENMARK ROBOT ASSEMBLY & CONTROLLER

(MODEL: GB3, GB4, GB4P, PRE ALIGNER)

♣ BROOKS ROBOT ASSEMBLY

(MODEL: MTR5, VTR5, Z-BOT)

♣ PRI (EQUIPE) ROBOT & PRE ALIGNER

ASSY & CONTROLLER

(MODEL: ATM-100, ATM-200, PRE ALIGNER)

♣ MECS ROBOT ASSEMBLY & CONTROLLER

(MODEL: UTS-100, 200, 800, 1000, 3400)

♣ FUSION ROBOT ASSEMBLY

♣ YASGAWA ROBOT ASSEMBLY ( MODEL : SV3 )

◈ GENMARK AUTOMATION

GB3 ROBOT

|

GB4 ROBOT

|

GB4P ROBOT

|

|

( 2 LINKS ) |

( 3 LINKS ) |

(2 LINKS ) |

◈ GENMARK AUTOMATION

|

GB7

ROBOT |

GB8 ROBOT |

GPR-SM

ROBOT |

|

|

|

( MULTI-JOINT ) |

|

(MULTI-JOINT) |

|

|

|

|

||

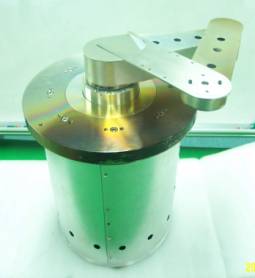

◈ GENMARK AUTOMATION

|

GB4P CONTROLLER |

GB4

CONTROLLER |

GB3

CONTROLLER |

|

|

|

|

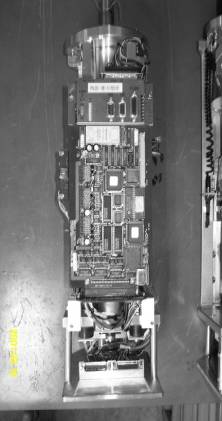

◈ BROOKS AUTOMATION

|

Z-BOT ROBOT |

MTR

5 ROBOT |

VTR

5 ROBOT |

|

( SINGLE ARM ) |

( DUAL ARM ) |

( SINGLE ARM ) |

◈ BROOKS AUTOMATION

|

MAG 7 ROBOT |

VCE 3 INDEX |

VCE

4 INDEX |

|

(

DUAL ARM ) |

(

VACUUM ) |

(

VACUUM ) |

◈ PRI AUTOMATION (EQUIPE)

|

ATM 100 ROBOT |

ATM

200 ROBOT |

ATM

300 ROBOT |

|

(

SINGLE ARM ) |

(

SINGLE ARM ) |

(

SINGLE ARM ) |

◈ PRI AUTOMATION (EQUIPE)

|

PRE ALIGNER |

ATM 100 CONTROLLER |

ATM 200/300 CONTROLLER |

|

|

|

|

◈ MECS AUTOMATION

|

UTC

100 ROBOT |

UTC

800 ROBOT |

UTC 3400 ROBOT |

|

(

SINGLE ARM ) |

(

SINGLE ARM ) |

(

DUAL ARM ) |

◈ MECS AUTOMATION

|

UTC

100 CONTROLLER |

UTC 800 CONTROLLER |

UTC

3400 CONTROLLER |

|

|

|

|

◈ FUSION AUTOMATION

|

FUSION ROBOT |

|

|

|

|

◈ YASGAWA AUTOMATION

|

SV3

ROBOT |

SV3

CONTROLLER |

|

|

(

MULTI-JOINT ) |

|

|

◈

YASGAWA AUTOMATION

|

XV-RCM4700

ROBOT |

XV-RCM4700 CONTROLLER |

(MULTI-JOINT)

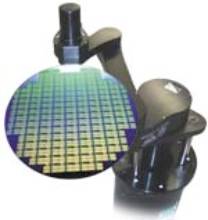

◈ ROBOT INSTALLATION STATE OF EACH SYSTEM

1. GENMARK ROBOT ASSEMBLY

. CANON STEPPER (APT-5800: CVD

PROCESS) – GB4

. GENUS SYSTEM (6000: CVD

PROCESS) – GB3

. AG (MEASUREMENT EQUIPMENT) – GB4

. FALCON SYSTEM (ETCH PROCESS) – GB4

. ULTRA TECH STEPPER (UTS:

PHOTO PROCESS) – GB4

. 4-POINT PROBE (OP2600:

MEASUREMENT) – GB4

2. BROOKS ROBOT ASSEMBLY

. NOVELLUS SYSTEM (CVD PROCESS)

– MTR5, VTR5, VCE3, VCE4

. GENUS SYSTEM (7000: CVD

PROCESS) – MTR5, VCE3, VCE4

. GASONIC SYSTEM (ETCH PROCESS)

– VTR3 (Z-BOT)

. LAM SYSTEM (ETCH PROCESS) – MTR5, VTR5,

VCE3, VCE4

. JOOSUNG SYSTEM (CVD PROCESS) – MTR5

3. EQUIPE ROBOT ASSEMBLY

. THERMA WAVE (OPTI PROBE 2600:

MEASUREMENT EQIPMENT) – ATM 100, ATM 200

. LASER MARKING (MESUREMENT

EQUIPMENT) – ATM 100, ATM 200, PRE ALIGNER

. TENCOR (SURFCAN: MEASUREMENT

EQUIPMENT) – ATM 100, ATM 200

. METRA 2155M (MEASUREMENT

EQUIPMENT) – ATM 100, ATM 200

. LUMONICS (MEASUREMENT

EQUIPMENT) – ATM 100, ATM 200

. AIT (MEASUREMENT EQUIPMENT) – ATM 100, ATM

200

4. MECS ROBOT ASSEMBLY

. W/J SYSTEM (CVD PROCESS) – UTS 800

. CANON SYSTEM (END FAB

PROCESS) – UTS 100

. SEM (MEASUREMENT EQUIPMENT) – UTS 800

. M511AE SYSTEM – UTS 100

. MAS 1800 SYSTEM (ETCH

PROCESS) – UTS 3400

. MAS 8000 SYSTEM (ETCH PROCESS) – UTS 1000

. CANON SYSTEM (ETCH PROCESS) – UTS 200

|

2.

ORGANIZATION |

|

TOP TECH |

![]()

|

LOCALIZATION OF PRODUCT |

|

ROBOT TEAM |

|

MANAGEMENT |

|

REFURBISHMENT |

|

LOCALIZATION OF PARTS |

|

FIELD SERVICE & SALES |

|

REPAIR & REFURBISHMENT |

|

ACCOUNTING |

|

FOREIGN AFFAIRS |

|

3.

SERVICE CONTRACT |

|

1. SAMSUNG ELECTRONICS CO., LTD : KI-HYUNG

FACTORY 2. HYNIX

SEMICONDUCTOR INC. : E-CHEON FACTORY 3. HYNIX SEMICONDUCTOR

INC. : CHEON-JU FACTORY 4. HYNIX

SEMICONDUCTOR INC. : GU-MI FACTORY 5. MEMC KOREA CO., LTD : CHEON-AN FACTORY 6. LG

SILTRON CO., LTD : E-CHEON FACTORY 7. LG

SILTRON CO., LTD : GU-MI FACTORY 8. FAIRCHILD KOREA : BU-CHEON FACTORY 9. KOREA

ELECTRONICS CO., LTD(K.E.C) : GU-MI FACTORY 10. ANAM

CO., LTD : BU-CHEON FACTORY |

|

|

4. LIST OF REPAIRED ROBOTS BY TOPTECH (2001.2002.2003) |

||

2003 01/03/03– 12/31/03

|

NO |

DESCIPTION |

C

U S T O M E R |

TOTAL

Q’TY |

||||||

|

SAMSUNG |

HYNIX |

LG |

MEMC |

KEC |

ANAM |

OTHERS |

|||

|

1 |

GENMARK ROBOTASSY & CONTROLLER |

50 |

11 |

5 |

3 |

- |

- |

3 |

72 |

|

2 |

EQUIP

ROBOT ASSY &

CONTROLLER |

14 |

6 |

3 |

4 |

- |

- |

2 |

29 |

|

3 |

PRE

ALIGNER ASSY &

CONTROLLER |

21 |

23 |

5 |

- |

- |

1 |

- |

49 |

|

4 |

BROOKS

ROBOT ASSEMBLY |

- |

27 |

- |

- |

- |

- |

- |

27 |

|

5 |

MECS

ROBOT ASSY &

CONTROLLER |

21 |

5 |

- |

- |

- |

2 |

2 |

30 |

|

6 |

FUSION

ROBOT ASSEMBLY |

10 |

- |

- |

- |

- |

- |

- |

10 |

|

7 |

OTHER

ROBOTS |

36 |

9 |

- |

- |

1 |

- |

5 |

51 |

|

TOTAL

(Q’TY) |

152 |

81 |

13 |

7 |

1 |

2 |

12 |

268 |

|

2002 01/03/02– 12/31/02

|

NO |

DESCIPTION |

CUSTOMER |

TOTAL

Q’TY |

|||||

|

SAMSUNG |

HYNIX |

LG |

POSCO |

KEC |

MECS |

|||

|

1 |

GENMARK ROBOTASSY & CONTROLLER |

81 |

24 |

3 |

- |

1 |

1 |

110 |

|

2 |

EQUIP

ROBOT ASSY &

CONTROLLER |

6 |

22 |

- |

- |

- |

- |

28 |

|

3 |

PRE

ALIGNER ASSY &

CONTROLLER |

9 |

13 |

- |

1 |

- |

- |

23 |

|

4 |

BROOKS

ROBOT ASSEMBLY |

16 |

16 |

- |

- |

- |

- |

32 |

|

5 |

MECS

ROBOT ASSY &

CONTROLLER |

8 |

6 |

1 |

- |

- |

- |

15 |

|

6 |

FUSION

ROBOT ASSEMBLY |

9 |

- |

- |

- |

- |

- |

9 |

|

7 |

OTHER

ROBOTS |

15 |

4 |

- |

- |

- |

- |

19 |

|

TOTAL

(Q’TY) |

144 |

85 |

4 |

1 |

1 |

1 |

236 |

|

2001 01/03/01-12/31/01

|

NO |

DESCIPTION |

CUSTOMER |

TOTAL

Q’TY |

|||||

|

SAMSUNG |

HYNIX |

LG |

POSCO |

KEC |

FAIRCHILD |

|||

|

1 |

GENMARK ROBOTASSY & CONTROLLER |

35 |

15 |

1 |

- |

- |

- |

51 |

|

2 |

EQUIP

ROBOT ASSY &

CONTROLLER |

10 |

25 |

1 |

1 |

2 |

3 |

42 |

|

3 |

PRE

ALIGNER ASSY &

CONTROLLER |

5 |

10 |

- |

1 |

- |

- |

16 |

|

4 |

BROOKS

ROBOT ASSEMBLY |

15 |

11 |

- |

- |

- |

- |

26 |

|

5 |

MECS

ROBOT ASSY &

CONTROLLER |

10 |

10 |

3 |

- |

- |

- |

23 |

|

6 |

FUSION

ROBOT ASSEMBLY |

11 |

- |

- |

- |

- |

- |

11 |

|

7 |

OTHER

ROBOTS |

5 |

1 |

- |

- |

- |

- |

6 |

|

TOTAL

(Q’TY) |

91 |

72 |

5 |

2 |

2 |

3 |

175 |

|

|

5. ROBOT ASSEMBLY |

|

NO |

PARTS DESCRIPTION |

PARTIAL OVERHAUL (2 YEARS ~ 4 YEARS) |

FULL OVERHAUL (MORE THAN 4 YEARS) |

REMARKS |

|

|

1 |

M O T O R |

Theta-Axis, Robot |

Clean up |

Exchange |

|

|

Radial-Axis, Robot |

〃 |

〃 |

|

||

Lift (Z)-Axis, Robot |

Exchange |

〃 |

|

||

|

End / Effect, Robot |

Clean up |

Exchange |

|

||

|

V-Motor for Pre- |

〃 |

〃 |

|

||

|

P-Motor for Pre- |

〃 |

〃 |

|

||

|

2 |

B E L T (9EA) |

T-Axis Drive #1 |

Exchange |

Exchange |

|

|

T-Axis Drive #2 |

〃 |

〃 |

|

||

|

R-Axis Drive #1 |

〃 |

〃 |

|

||

|

R-Axis Drive #2 |

〃 |

〃 |

|

||

|

R-Axis Drive #3 |

〃 |

〃 |

|

||

|

R-Axis Drive #4 |

〃 |

〃 |

|

||

|

Z-Axis Drive #1 |

〃 |

〃 |

|

||

|

E/E Drive #1 |

〃 |

〃 |

|

||

|

E/E Drive #2 |

〃 |

〃 |

|

||

|

NO |

PARTS DESCRIPTION |

PARTIAL OVERHAUL (2 YEARS ~ 4 YEARS) |

FULL OVERHAUL (MORE THAN 4YEARS) |

REMARKS |

|

|

3 |

B E A R I N G (16EA) |

Z-Axis Shaft #1 |

Exchange |

Exchange |

|

|

Z-Axis Shaft #2 |

〃 |

〃 |

|

||

|

R-Axis Shaft #1 |

〃 |

〃 |

|

||

|

R-Axis Shaft #2 |

〃 |

〃 |

|

||

|

R-Axis Shaft #3 |

〃 |

〃 |

|

||

|

R-Axis Shaft #4 |

〃 |

〃 |

|

||

|

R-Axis Shaft #5 |

Clean up |

〃 |

|

||

|

R-Axis Shaft #6 |

〃 |

〃 |

|

||

|

T-Axis Drive #1 |

Exchange |

〃 |

|

||

|

T-Axis Drive #2 |

〃 |

〃 |

|

||

|

T-Axis Drive #3 |

〃 |

〃 |

|

||

|

T-Axis Drive #4 |

Clean up |

〃 |

|

||

|

Arm Links #1 |

Exchange |

〃 |

|

||

|

Arm Links #2 |

〃 |

〃 |

|

||

|

Arm Links #3 |

〃 |

〃 |

|

||

|

Arm Links #4 |

〃 |

〃 |

|

||

|

Arm Links #5 |

〃 |

〃 |

|

||

|

Arm Links #6 |

〃 |

〃 |

|

||

|

NO |

PARTS DESCRIPTION |

PARTIAL OVERHAUL (2 YEARS ~ 4 YEARS) |

FULL OVERHAUL (MORE THAN 4 YEARS) |

REMARKS |

|

|

4 |

S H A F T |

Main Body #1 |

Clean up |

Exchange |

|

|

Vertical #1 |

〃 |

〃 |

|

||

|

Vertical #2 |

〃 |

〃 |

|

||

|

5 |

P U L L E Y (9EA) |

T-Axis Drive #1 |

Exchange |

Exchange |

|

|

T-Axis Drive #2 |

Clean up |

Clean up |

|

||

|

T-Axis Drive #3 |

〃 |

〃 |

|

||

|

R-Axis Drive #1 |

Exchange |

Exchange |

|

||

|

R-Axis Drive #2 |

Clean up |

Clean up |

|

||

|

R-Axis Drive #3 |

〃 |

〃 |

|

||

|

R-Axis Drive #4 |

〃 |

〃 |

|

||

|

R-Axis Drive #5 |

〃 |

〃 |

|

||

|

R-Axis Drive #6 |

〃 |

〃 |

|

||

|

R-Axis Drive #7 |

〃 |

〃 |

|

||

|

Z-Axis Drive #1 |

Exchange |

Exchange |

|

||

|

Z-Axis Drive #2 |

Clean up |

Clean up |

|

||

|

Arm Links #1 |

〃 |

〃 |

|

||

|

Arm Links #2 |

〃 |

〃 |

|

||

|

Arm Links #3 |

〃 |

〃 |

|

||

|

Arm Links #4 |

〃 |

〃 |

|

||

|

NO |

PARTS DESCRIPTION |

PARTIAL OVERHAUL (2 YEARS ~ 4 YEARS) |

FULL OVERHAUL (MORE THAN 4 YEARS) |

REMARKS |

|

|

6 |

Main

Leadscrew (2EA) |

Clean

up & Oil Charge |

Exchange |

|

|

|

7 |

S E N S O R |

Vacuum #1 |

Adjust |

Adjust |

|

|

Vacuum #2 |

〃 |

〃 |

|

||

|

T-Axis Home |

〃 |

〃 |

|

||

|

R-Axis Home |

〃 |

〃 |

|

||

|

Z-Axis Home |

〃 |

〃 |

|

||

|

LIFE

TIME OF EACH PARTS |

1)

LIFE TIME OF ROBOT ASSEMBLY

RECOMMENDED BY GENMARK : 5 YEARS (US)

RECOMMENDED IN KOREA : 4 YEARS (KOREA)

2)

LIFE TIME OF PARTS

|

|

US |

KOREA |

|

THETA MOTOR |

5 YEARS |

3 ~ 4 YEARS |

|

RADIA MOTOR |

5 YEARS |

3 ~ 4 YEARS |

|

LIFT(Z) MOTOR |

4 YEARS |

2 ~ 3 YEARS |

|

BEARINGS |

5 YEARS |

|

|

BELTS |

5 YEARS |

Abrasion rate for 2 years (40%) 3 years (60%) 4 years (90%) |

|

PULLEY |

7 YEARS |

4 years (25%) 5 years (45%) 6 years (80%) |

|

LEADSCREW ASSY |

5 ~ 6 YEARS |

3 years (30%) 4 years (50%) 5 years (80%) |